Intuitive Biosensor to Measure the Sugar Content of Oat and Rice Drinks

OatSens® is an innovative biosensor system designed to measure the glucose and maltose content in sugar free vegan drinks quickly and accurately.

Why and where should I use OatSens®

During oat and rice drink production, starch is mainly hydrolyzed to the sugars glucose and maltose. These two sugars determine the sugar content and are crucial for the sweetness of the drink.

To achieve constant product quality sugar levels can be monitored at following processing steps:

- Product Development:

Determine the ideal amount of enzymes for the fermentation process. Develop new oat-based products to meet changing customer and market preferences.

- Process Optimization:

Check the influence of different raw materials, enzyme dosages and processing times on your manufacturing process.

- Batch-release:

Ensure by quality control that the produced batch meets the specifications.

- Scale-up of Production:

Validate the performance of a new production line.

Simple and Fast

3 minutes time to result

Excellent accuracy

Easy test protocol

Optimized for oat and rice drinks

Best solution for

Prompt product release

Full documentation

Development support

Process optimization

In-Process control

OatSens® Products

OatSens® Assay Kit

resilient, robust, reliable

- Quantitation range glucose: 0.1 - 1%

- Quantitation range maltose: 0.1 - 1%

- Factory calibrated

- Optimzed for sugar free oat drinks

DirectSens Reader Kit

portable and intuitive

- Small, portable device

- Intuitive software

- Immediately ready to use

Bring oat drinks to room temperature, dilute with ready-to-use buffer and mix until homogeneous. This simple procedure enables results equivalent to the reference method HPLC.

Switch on the DirectSens Reader and start the OatSens® software

The OatSens® Reader Kit provides hardware and software that will allow you to get precise glucose and maltose measurements when used with the OatSens® biosensors. The intuitive software guides you through the assay procedure step by step.

Transfer necessary information with a single scan

Each individually packed sensor is labeled with a QR code containing the key parameters like batch specific collaboration data, expiry date or sensor batch name. Factory calibration enables quick start without running a calibration.

Apply sample to the sensor and wait for one min.

Once the OatSens® Reader detects the first contact of the sample at the sensor there is nothing more to do. Just wait 50 seconds until results are displayed.

Take immidiate decisions based on results

Final results are displayed immidiately. No need for cumbersome calculations. You can choose from several output formats (.xls, .csv, .PDF) to store the data or easily transfer it into your LIMS system.

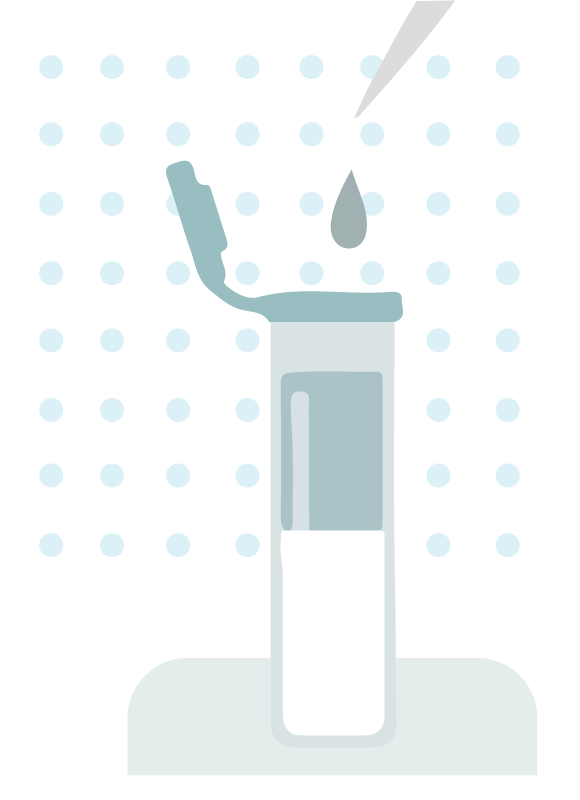

DILUTE

Simple sample preparation

Bring oat drinks to room temperature, dilute with ready-to-use buffer and mix until homogeneous. This simple procedure enables results equivalent to the reference method HPLC.

CONNECT

Switch on the DirectSens Reader and start the OatSens® software

The OatSens® Reader Kit provides hardware and software that will allow you to get precise glucose and maltose measurements when used with the OatSens® biosensors. The intuitive software guides you through the assay procedure step by step.

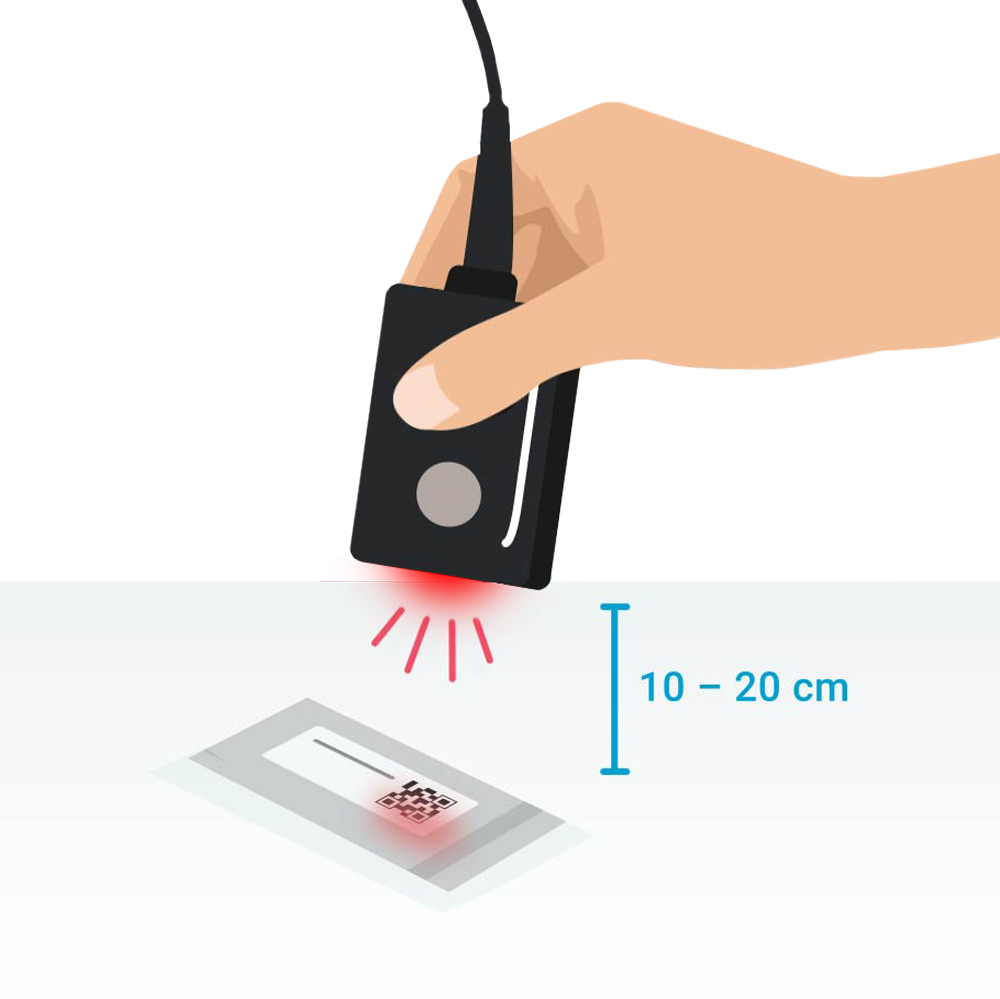

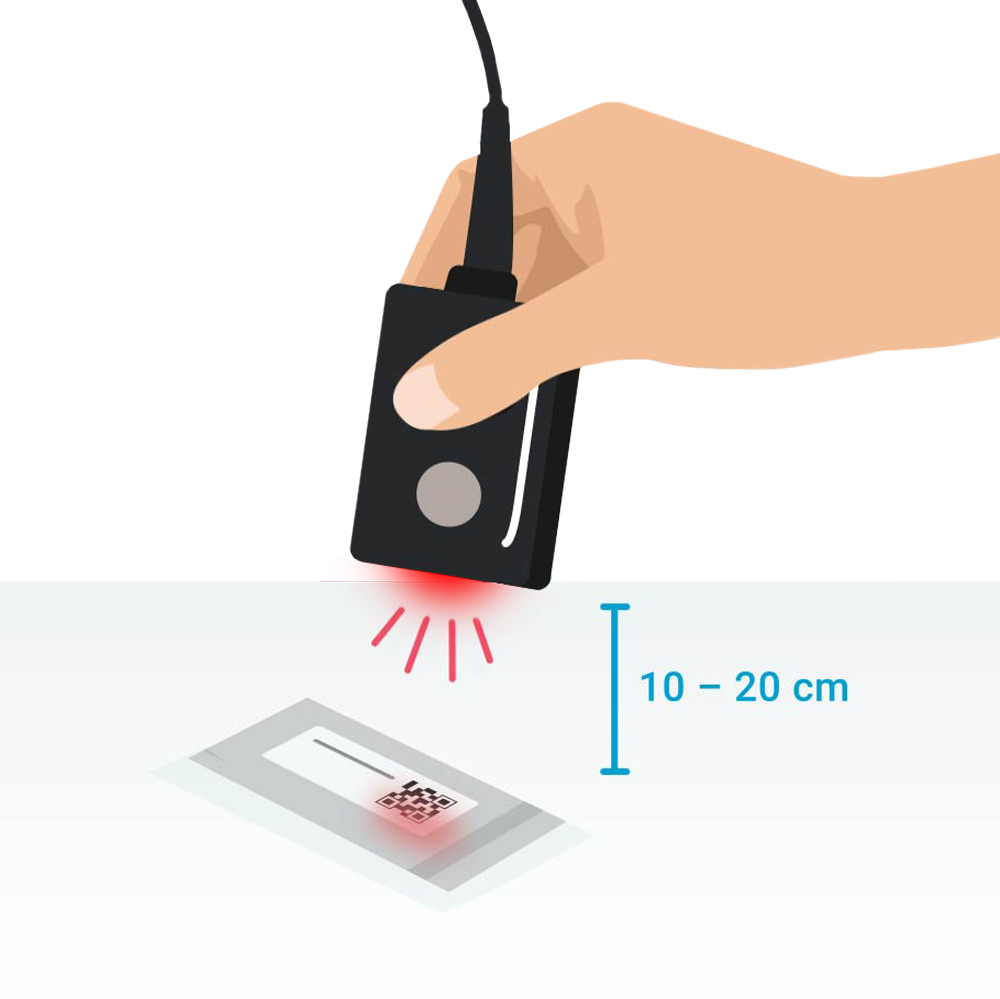

SCAN

Transfer necessary information with a single scan

Each individually packed sensor is labeled with a QR code containing the key parameters like batch specific collaboration data, expiry date or sensor batch name. Factory calibration enables quick start without running a calibration.

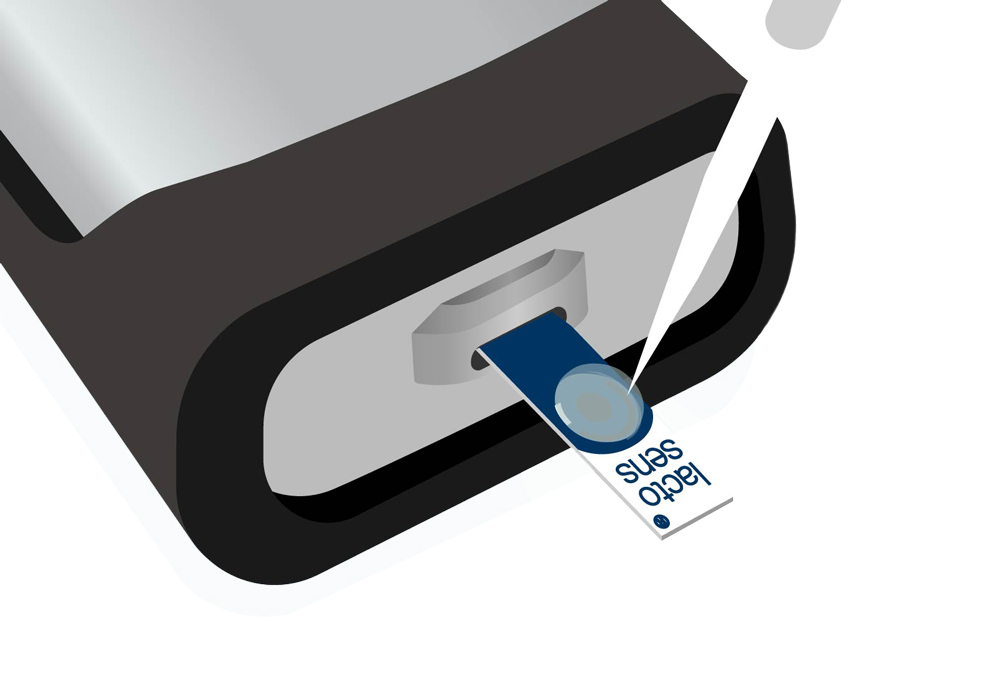

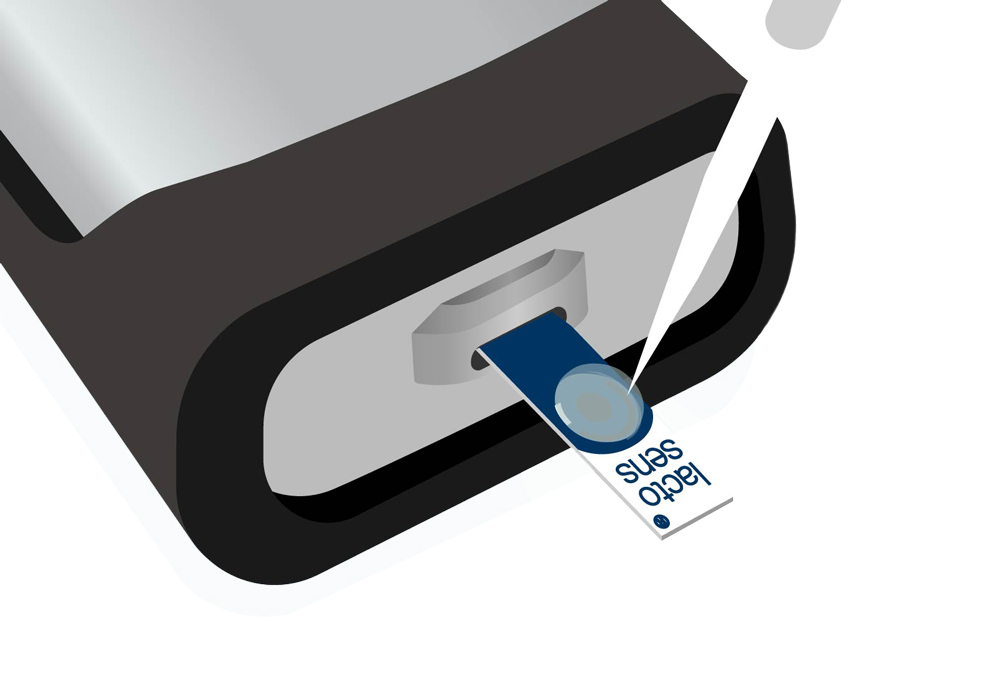

MEASURE

Apply sample to the sensor and wait for one min.

Once the OatSens® Reader detects the first contact of the sample at the sensor there is nothing more to do. Just wait 50 seconds until results are displayed.

DECIDE

Take immidiate decisions based on results

Final results are displayed immidiately. No need for cumbersome calculations. You can choose from several output formats (.xls, .csv, .PDF) to store the data or easily transfer it into your LIMS system.

DirectSens® Reader Kit

Training Video

Sign Up for our Newsletter

Keep up with the latest developments in oat drink analysis and OatSens® innovations by subscribing to our newsletter or contacting our team for personalized information